Chemical Division Chemicals Division

High Dispersion Elements

Taihei Chemicals manufactures and processes the following dispersion elements.

Solid dispersion elements (hi-di Color Chips)

1.NC chips (pigments dispersed in industrial nitrocellulose)

Carbon black: 10%-40% pigment concentration

Inorganic pigments: 60%-80% pigment concentration

Organic pigments: 20%-60% pigment concentration

2.Resin chips

Carbon black: 20%-70% pigment concentration

Inorganic pigments: 60%-85% pigment concentration

Organic pigments: 20%-70% pigment concentration

About Nitrocellulose

Nitrocellulose is a natural cellulose that has been treated with nitric acid to form a nitric acid ester for use in industry, plastics, and explosives.

Industrial nitrocellulose can be dissolved in a number of solvents and used as paints and inks.

Nitrocellulose Features

・Exceptional coating strength and elasticity・A high level of surface hardness

・Excellent compatibility with other resins

・Excellent dispersion with various pigments

・High rates of drying when used as a coating compared with other resins

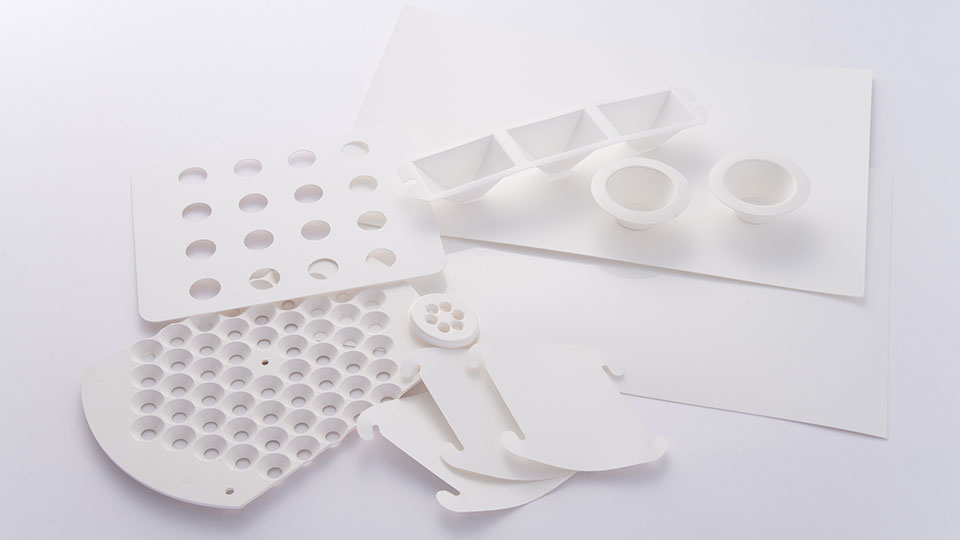

Liquid dispersion element

Structure

8%-15% pigment concentration (20%-30% for solid portion)

Other dispersion elements

We offer products for various application requirements, including high dispersal, high concentration, eco-friendliness, and conductivity stability.

Applications

About the Technologies

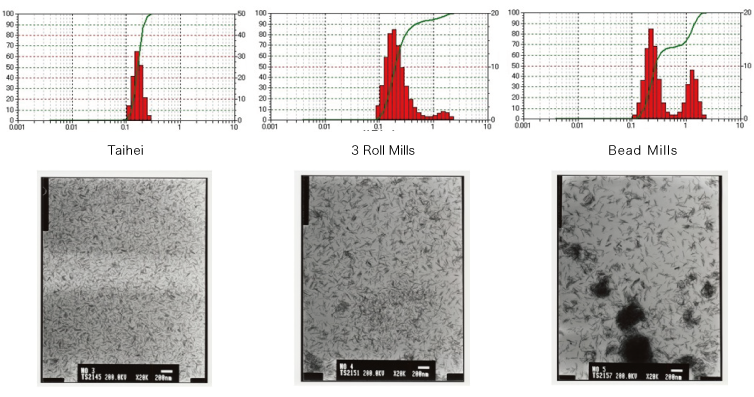

●High Dispersion Product Features

[Feature 1] No need for grinding

As dispersion has already been done, toners, inks, and other products can be made simply by dissolving.[Feature 2] Easy to handle

Our solid dispersed products are shaped like chips, so there's no need to worry about powder dispersal or paste-like stickiness.Moreover, uniform composition allows for accurate and constant mixing ratios.

This reduces variation from lot to lot.

We also offer these chips as dissolution products (liquid dispersion products) based on the needs of the customer.

[Feature 3] Cost savings

Eliminating the dispersion process means not needing grinding machines.Dissolve only as much as you need when you need, and eliminate waste.

[Feature 4] High-quality paint and ink production

Pigment dispersion results in pigments being evenly dispersed to a sophisticated degree, resulting in products that excel in coating luster, transparency, color expression, and tinting strength.

●Fields of Application

◇Cosmetics: Manicures, bath products◇Rubber products: Semiconductor compounds, sports equipment

◇Information technology: Flame retardants, color toners, inkjet color filters

◇Plastic products: Cards, coloring agents, conductive materials

◇Paints: Construction, leather, automobiles, plastics, stationery, construction materials, UV-blocking materials, water-based materials

◇Inks: Inks used in gravure, markers, screens, offsets, magnetic tape, and conductive products